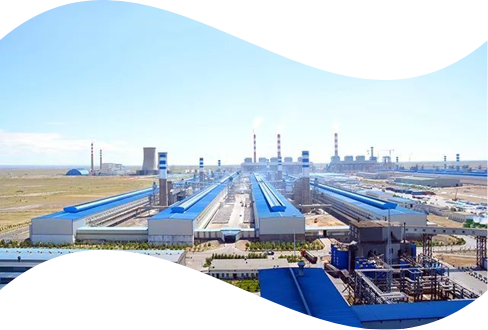

HENGLI Petrochemical 40 million / year ton of oil refining integration project

| ZHEJIANG Petrochemical 40 million / year ton of oil refining integration project | LIANYUNGANG Petrochemical

3.2 million tons / young hydrocarbon comprehensive | YISHENG New Material The 6.6 million tons / year of the PTA project

| CNOOC Huizhou Refining & Chemical Co

Huilian Phase II, 22 million / year ton of oil refining

Reconstruction and expansion project | Sinopec Zhenhai Refining & Chemical Company

1.2 million / year ton ethylene renovation and expansion project | Wanhua Chemical

480,000 tons / year bisphenol A integration project | GUANGXI Huayi New Materials Integration project of new chemical materials

| CNOOC Shell The SMPO & POD project

| China AtlantoShaanxi Coal Chemical Industry: 1.8 million tons /

year ethylene glycol project |

|  |  |  |  |  |  |  |  |  |

Hainan Huasheng

2.26 million tons / year non-photogamic polycarbonate project | Shenghong Refining

The 16 million tons / year oil refining project | Anhui Haoyuan Chemical Industry

300,000 tons / year ethylene glycol project | Heilongjiang Longyou Petrochemical Company5.5 million tons / year

heavy oil catalytic pyrolysis project | HuaLu Hengsheng

500,000 tons / year ethylene glycol project | Baofeng Energy600,000 tons / year methanol to olefin project | Jiangnan Shipyard (98000m³ liquefied ethane ship, etc.)

Brand number: 316 / 316L, delivery time: 2020.12 | Keppel shipyard in Singapore (FLNG ship)

Brand number: 316 / 316L, delivery time: 2020.1 | Guangzhou Wenchong Shipyard (Super double-phase steel

desulfurization tower)

Brand number: S32750 Delivery time: 2021.3 | CSSC Dalian (FPSO, MV31, etc.)

Brand number: 316L, etc., delivery date, 2019.8 |

|  |  |  |  |  |  |  |  |  |

| 725 Institute of China Shipbuilding Industry (Cu-Ni alloy Tube) | Nantong COCSO Shipyard (FSRU ship module) | CIMC Raffles (Drilling Rig) | CNOOC Orient 13-2 (Lined pipe) | CNOOC Bozhong 19-6 (Lined Pipe) | Petrobras MODEC FPSO (COSCO Shipping) | CNOOC Guangxi LNG, storage and transportation storage Brand number: 304 / 304L

Specification: (8 "~32")×(3.76~9.53mm) | CNOOC Zhejiang LNG Phase II Brand number: 304 / 304L

Specification: (6 "~28")×(7.11~10.31mm) | Sinopec Shandong LNG Phase II Brand number: 304 / 304L

Specification: DN250 SCH10S | LIANYUNGANG Petrochemical

A 4X160000m³ low-temperature ethane storage tank

Brand number: 304 / 304L

Specification: 813X12.7MM

Delivery time: 2020.9 |

|  |  |  |  |  |  |  |  |  |

Sinopec Luoyang Institute

Wenzhou LNG terminal

Brand number: 304 / 304L

Specification: 219.1~711X12.7MM

Delivery time: 2022.3 | Huatai Shengfu

160,000 m ³ low-temperature ethane storage tank

Brand number: 304 / 304L

Specification: 219~508X9.53MM | YAMAL LNG

Brand number: 304 / 304L

Specification: 406~914X9.53MM | Beijing Maiden Voyage | Oriental Hope | Sichuan Yongxiang

70,000 tons / year high purity polysilicon project | Xinjiang Daquan

25,000 tons / year high purity polysilicon project | Eagle Central China Paper Industry

500,000 tons of box board project | Guangxi Sun Paper

3.5 million tons of forest pulp and paper integration project | APP for Asian pulp and paper Chemical machine pulp and sewage treatment project |

|  |  |  |  |  |  |  |  |  |

TCL Shenzhen Huaxing Optoelectronics semiconductor clean pipeline

project | Beijing Daxing Airport | Hong Kong-Zhuhai-Macau/Macao Bridge Tubes used for stainless steel construction

| CNNC Xiapu nuclear Power Plant

Fast reactor demonstration project of CNNC 2.3 | CONBA

Stainless steel pipe for pharmaceutical engineering | Shenghong Refining

Stainless steel associated heat pipe | Hangzhou Sewage Treatment Plant

Stainless steel pipe for backwash purification unit | Qilu Pharmaceutical

Fluid stainless steel pipe for raw material delivery | Zijin Mining

Wet copper smelting, stainless steel sewage pipe | ect |

|  |  |  |  |  |  |  |  | …… |